load unload test in compressed air|Unload Running Explained : mail order As pressure rises, the reverse occurs. The last one on will load and unload once the number of air compressors running stabilizes. Then came programmable logic controllers (PLCs), basically automating the function. . Resultado da Earth Mama ist ein Filmdrama von Savanah Leaf, das im Januar 2023 beim Sundance Film Festival seine Premiere feierte und im Juli 2023 in die US-Kinos kam. Handlung. Gia ist schwanger, und bereits ihr Sohn und ihre Tochter sind in Pflegefamilien untergekommen. Die junge Mutter .

{plog:ftitle_list}

web6 dias atrás · Have fun stretching with Yoga Dice from ThinkFun! In this fun game of rolling and posing, kids build flexibility and focus while practicing 36 different yoga poses. Players roll a pose; if they can hold it for the .

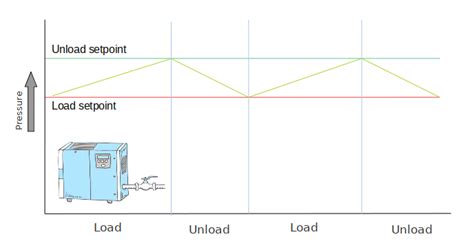

What is air compressor load/unload/stop control? The most common regulation principles for displacement compressors dictate whether air is produced or not. When air is required, a signal is sent to the solenoid valve which guides the . Leak estimates can be done on load/unload compressors simply using a stopwatch and a cell phone calculator. Using this equation, and your observations, we can estimate that your compressor is loaded at 87/(87+64) .

As pressure rises, the reverse occurs. The last one on will load and unload once the number of air compressors running stabilizes. Then came programmable logic controllers (PLCs), basically automating the function. . Compressed air system controls match the compressed air supply with system demand and are one of the most important determinants of overall system energy efficiency. Proper control is essential to efficient system operation and high performance. “While there are other actions that impact on energy usage to produce compressed air, a properly applied and .

The compressed air manual is unique of its kind and has been widely used and hugely appreciated by many thousands of interested readers over the years. We are now proud to present the eight . 2.5.2.9 Load–unload–stop 55 2.5.3 Regulation principles for dynamic compressors 56 2.5.3.1 Inlet regulation 3.2.5 Filters56 If you have a lubricated screw compressor running in load/unload mode, you should be aware that the compressor cycle times greatly affect the efficiency of your compressed air system. The cycle time is the amount of time it takes for the compressor to load and unload while supplying your compressed air needs.What the unloader valve does is that is responds to the compressor pressure switch turning the power off to the motor and allows any air that may be trapped over the piston, or pistons on a multi-cylinder air compressor, to vent to atmosphere, removing any load that the trapped air may have created over the cylinder piston. A compressor operating in a load/unload mode isn’t as restricted in terms of run time or starts/hr. The load/unload mode is best suited in applications where the compressor is supplying most of the air instantaneously rather than relying on receiver storage. . Determine the compressed air load on a system consisting of two air-cooled, oil .

a. Incomplete integration: The minimum command is given to the compressor by the sequencer, “make air”. If the compressor is making little or no air because of local unloading or modulation, the sequencer will start and load the next compressor at part load. The sequencer is “unaware” of this. b.

Figure 1 shows the test data for a 100 hp VFD controlled, air-cooled oil-injected air compressor from the same manufacturer. We can see the unit has been tested at 125 psig discharge pressure, 10 psi higher than the fixed-speed air compressor, and that there are five test points somewhat equidistant between points between minimum and maximum speed.

For example, ISO 1217 relates to performance testing of displacement air compressors. This standard includes packaged rotary screw air compressors as well. Clause 3.4.1 of ISO1217 states: “Actual volume flow rate of a compressor is the actual volume of gas, compressed and delivered at the standard discharge point, referred to conditions of .%PDF-1.7 %âãÏÓ 266 0 obj > endobj xref 266 36 0000000016 00000 n 0000002244 00000 n 0000002420 00000 n 0000002884 00000 n 0000002921 00000 n 0000003033 00000 n 0000003147 00000 n 0000004307 00000 n 0000004906 00000 n 0000005539 00000 n 0000006148 00000 n 0000006753 00000 n 0000007002 00000 n 0000007669 00000 n . An air compressor unloader valve is a device that helps regulate the amount of air pressure that is released from the compressor when it is turned off. This valve is located in the compressor’s head and is responsible for allowing the compressed air to escape from the discharge line, ensuring that there is no excess pressure built up within . To sequentially load or unload the other two compressors as the change of compressed air demand, the load/unload pressure of the second and the third compressor were set at 0.672/0.685 MPa and 0.675/0.685MPa, respectively. . (2000) A semi-empirical method for representing domestic refrigerator/freezer compressor calorimeter test data, .

Compressor Duty Cycle – If you don’t have a flow meter, and your compressors run in load/unload mode, you can estimate the leakage flow by timing both the load and unload cycle during a time when there is no production. The loaded time divided by the total cycle time of the compressor (loaded plus unloaded) gives you a fraction you can use to roughly calculate .Typically, air-testing laboratories provide compressed air testing kits for the end user to take a sample on-site and ship it to the laboratory for analysis. . When a load/unload control scheme is combined with a timer to stop the .Compressed Air Leakage Test Formula. a typical system should average around 4 cfm each and a high leak system should average around 5 cfm each. . leak estimates can be done on load/unload compressors simply using a stopwatch and a cell phone calculator. air leak test of your installation verifies and measures the reason for compressed air . By Ron Marshall for the Compressed Air Challenge The Compressed Air and Gas Institute’s data sheets can make a real difference in helping you choose your . Because two of the manufacturers have chosen to .

Food and beverage processing plants with varying air requirements for cleaning and packaging. Sandblasting operations where air demand fluctuates depending on the workload. On-Load/Off-Load (OL/OL) Compressor: Ideal for: Constant Air Demand: OL/OL compressors are well-suited for applications with a relatively constant air demand profile. These . As readers of this publication know, there are many ways to save energy in industrial compressed air systems. One common supply side technology is the variable frequency drive (VFD) of the compressor. It is well-documented that positive-displacement compressors with VFDs provide cost-effective savings in comparison to inlet modulating, load . An air compressor unloader valve is a critical component of an air compressor system. This valve serves to release the pressure inside the compressor’s air tank when the unit stops running. By doing so, it prevents the compressor from starting under load, which can cause excessive wear on the motor and may lead to startup failures.

Background. In Part 1, I made the case that full system commissioning is needed whenever a compressed air system is significantly modified.And I suggested the following definition of commissioning: “Compressed air system commissioning is the process for measuring, testing, adjusting, and documenting that the performance of an entire . Compressor unloader valve parts. Armature (A): The metallic cylinder upon which the coil is wound Inlet port (B): The air enters the solenoid valve through this port. Coil (C): A cylindrical, hollow coil made from enameled copper wire. This coil stores energy in a magnetic field through induction. Spring and plunger (D): When no magnetic field exists in the coil, the .If the compressor starts under load, it can cause the motor to stall or trip the circuit breaker. The unloader valve releases the compressed air from the tank, allowing the compressor to start without any load. This prevents overloading and extends the life of the compressor. . One of the most common problems with compressor unloader valves .

One such opportunity lies in installing an air compressor with a variable frequency drive (VFD) or retrofitting the company’s existing air compressors with VFDs. . If the requirement is 900 cfm, the base load will be shared by load-unload compressor of 400 cfm and the trim load will be shared by the 500 cfm VFD compressor. With such . The lubricated compressor load/unload curve is shown in Figure 3, the shape of the curve is not linear and varies with storage size, pressure band width, and sump blowdown time. What usually happens in the field is the auditor assumes one certain curve, but the compressor is really operating on another, due to mis-adjustment or some other issue .

Unload Running Explained

Air compressor load/unload/stop control systems

1. Air Compressor Amps vs. Pressure. This shows how the air compressor responds to pressure, basically an air compressor controls plot. See Figure 1 for an example of load-unload control. This came from a project where the air compressor was a centrifugal, and was in full blow-off instead of fully unloaded.

Unload/No load Compressor operation in which no air is delivered because the intake is closed or modified not to allow inlet air to be trapped. Literature and References Reference Books. Natural Resources Canada. “Compressors and Turbines” ISBN 0-662-14166-0, 1987; Scales, William. “Best Practices for Compressed Air Systems”, 2003

WEBWJCASINOGame oferece o melhor dos populares jogos de cassino. Virtual, Caça-níqueis, Futebol, Poker, Crash, Roleta e Roda da Fortuna! Come join me, become the next millionaire WJCASINO App. Baixe o APP e ganhe um bônus grátis de R$9,00. BAIXE . Entrar. 1*****34 .

load unload test in compressed air|Unload Running Explained